All Products

Customized Metal Fiber Burner with 800kw/m2 Infrared Combustion and 3 Years Warranty for Gas Boiler Applications

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Material | Fecral/430J1L | Application | Gas Boilder |

|---|---|---|---|

| Color | Metal Color | Warranty | 3 Years |

| Length | Customized Under Request | Infrared Combustion Mode | 800kw/m2 |

| Highlight | 800kw/m2 Metal Fiber Burner,corrosion proof Metal Fiber Burner,SGS certification Metal Fiber Burner |

||

Product Description

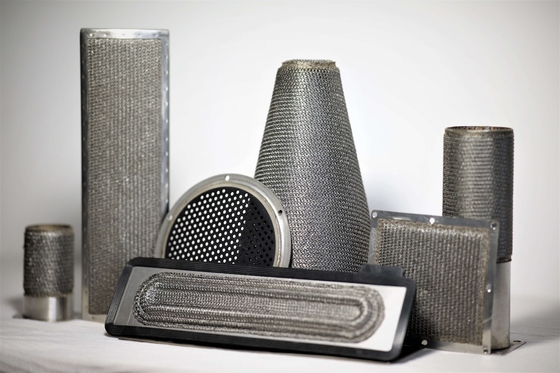

Customized Metal Fiber Burners According to Users Application

Description and Features

Through specialized designs of burner surface coverings, gas distribution metal plates, shape structures, and combination methods, our metal fiber burners precisely adapt to various working conditions and meet diverse application requirements.

Regular Customization Solutions

-

Surface Covering Adjustment: By modifying key parameters or using multiple coverings, we optimize burner performance for specific needs.

Example: The customized K2000/180-ULT enhances anti-flashback performance compared to standard K1400 fabric, making it ideal for demanding combustion scenarios.

-

Air Distribution Plate Design: Custom hole patterns solve issues with flame distribution, blockage, combustion resonance, and ignition.

Example: Special 3D structured holes improve dust passage rates and maintenance intervals.

-

Structural Design: Alternative shapes address limitations of traditional cylindrical/flat burners in heat exchange systems.

Example: Cone-type, internal burning, or partial-flame cylindrical designs meet unique heat transfer requirements.

-

Combination Methods:

- Multi-layer coverings enhance operational stability and reduce abnormal conditions

- Fabric-free designs with specialized distribution plates maintain stable operation within power limits

Example: Double-layer coverings improve thermal insulation, while steel tube designs reduce costs and eliminate clogging issues.

Standard Flat Hole Steel Cylinder Burner Example

Recommended Products