High Performance Conductive Plastic Masterbatch

| Material | Steel Fiber 60% & 75%& 25% Content | Properties | Conductive Material |

|---|---|---|---|

| Application | Medical Brackets | Color | Gray |

| Product Name | Plastic Conductive Masterbatch | Certification | ROHS,Reach |

| Highlight | Reach plastic conductive masterbatch,MFA 30% plastic conductive masterbatch,rust resistant plastic conductive masterbatch |

||

High Permance Conductive Masterbatch

1)Product Description

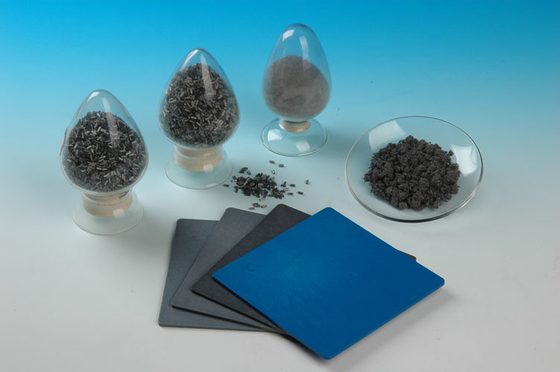

It is made of high-strength ultra-fine stainless steel fiber with resin and resin glue through a special process . It has little impact on the body material and only need one-time injection molding. Easy to process, no need electroplating & brushing conductive coating,light weight and can be dyed, free design and can reduce consumption.

2)Product Specs

| Diameter(μm) | 6.5µm,8 µm,11 µm | ±10 % |

| Masterbatch Length(mm) | 4-10 mm | ±10 % |

| Masterbatch Diameter(mm) | 2 | ±5 % |

| Masterbatch External Appearance | Smooth Surface without Broken | |

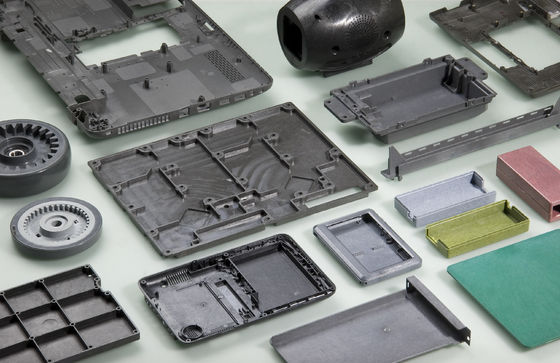

2)Application

Anti-static turnover boxes, shells and structural parts of explosion-proof products in the production process of precision electronic components in the field of electronics and electrical appliances.

EMI shielding shells for electrical products in the fields of telecommunications, computers, automotive electronic products.

Anti-static casters, PVC anti-static floor.

| Model | Metal Fiber Proportion | Usage | Applicable Resin |

| HT-CH60-T20 | 60% | ESD/EMI | PEI,PPO,PET/PETG,PBT,PC,PSU,PC/ABS |

| HT-CH60-T16 | 60% | ESD/EMI | PET/PETG,PBT,PA |

| HT-CH60-T14 | 60% | ESD/EMI | AS/ABS/SAN/ASA |

| HT-CH60-T12 | 60% | ESD/EMI | TPE,TPU,PE,PVC,POM,PP,PS |

| HT-CH75-T20 | 75% | ESD/EMI | PEI,PPO,PET/PETG,PBT,PC,PSU,PC/ABS |

| HT-CH75-T16 | 75% | ESD/EMI | PET/PETG,PBT,PA |

| HT-CH75-T14 | 75% | ESD/EMI | AS/ABS/SAN/ASA |

| HT-CH75-T12 | 75% | ESD/EMI | TPE,TPU,PE,PVC,POM,PP,PS |

4)Package

By Plastic bag, one bag with 25kg, outer package with carton box

![]()