Reach Approved 10000f Filament Conductive Masterbatch For Signal Wire

| Material | PFA 40% | Properties | Conductive Material |

|---|---|---|---|

| Application | Medical Brackets | Color | Black |

| Cutting Length | 5mm | ||

| Highlight | 10000f filament Conductive Masterbatch,Reach approved Conductive Masterbatch,10000f filament conductive plastic pellets |

||

Product Name: Conductive Plastic Agglomerates

Description:

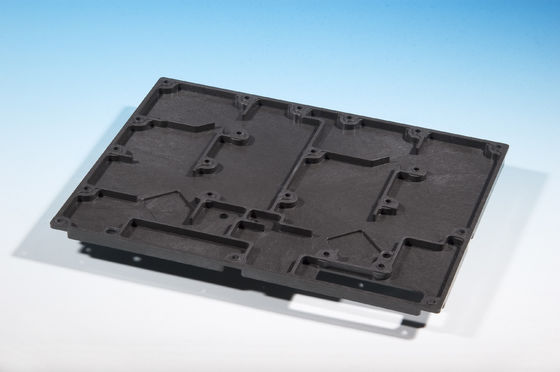

Huitong Conductive pellet is a stainless steel filler material used in plastic compounds to provide electrically conductive properties. It is frequently used to replace metal dye-cast in the automotive industry in order to reduce weight while still providing excellent shielding effectiveness.

It can be used as a masterbatch and has been designed for easy dispersion into the polymer matrix for injection molding (dry blend) and compounding.

Features:

* High shielding effectiveness at low load levels

* Lightweight metal replacements

* Compatible with any color additive

* Low impact on mechanical properties

Range Of Application: Plastic products such as PVC, PP, PA, PC, TPU, PE and ABS are available. It is easy to color and recyclable.

ENGINEERING AND PRODUCT SUPPORT

Our experienced engineers are available to help with optimal material selection and manufacturing strategies for each project. This includes support to ensure properly matched EMI gaskets, product design strategies, tooling, and other needs.

Technical Parameter:

| Fiber Diameter(m) | 12 |

| Fiber Filaments (f) | 5000~10000 |

| Agglomerate length(mm) | 1~10 (its length should be consistent for same specification) |

| Agglomerate Diameter (mm) | 2 |

| Agglomerate External Appearance | the surface is smooth |

Packing:

No Packaging Size Limitations

Dry blends (that use multiple pellet mixtures) have packaging limitations – they are sold only in smaller bags or containers, and carry the risk of the heavier pellets settling during transportation.

When settling occurs, it results in inconsistency in shielding and mechanical performance. Large volume programs can save significant labor hours by using single pellet products such as PREMIER.